LVT Floor Purchase Guide: 5 steps to accurately avoid pits, choose the right one and do not step on the mine

LVT flooring has become a popular home decoration with its soft foot feel and rich colors. Faced with the dazzling array of products on the market, how to accurately avoid pitfalls? This article extracts 5 steps of core rules to help you efficiently select the adaptive floor.

1. Select performance by scenario: Locking core requirements

Bedroom / Children’s Room: Comfortable and quiet priority

Choose a 4mm + thick model with IXPE buffer layer, and the wear-resistant layer is 0.2-0.3mm. It is recommended to design light wood grain or carpet grain to create a warm atmosphere.

Living room / High frequency zone: Wear resistance and impact resistance is king

Preferred choice of matte models with wear-resistant layer ≥0.3mm and substrate density ≥1.2g/cm³ is preferred to avoid scratches on smooth surfaces, and is suitable for frequent furniture movement scenarios.

Kitchen / Semi-open area: Waterproof and non-slip are key

Choose lock type LVT, edge sealing wax treatment, anti-slip level ≥R10. The expansion rate should be <1% during the actual soaking 24 hours, which is resistant to oil and stains and easy to clean.

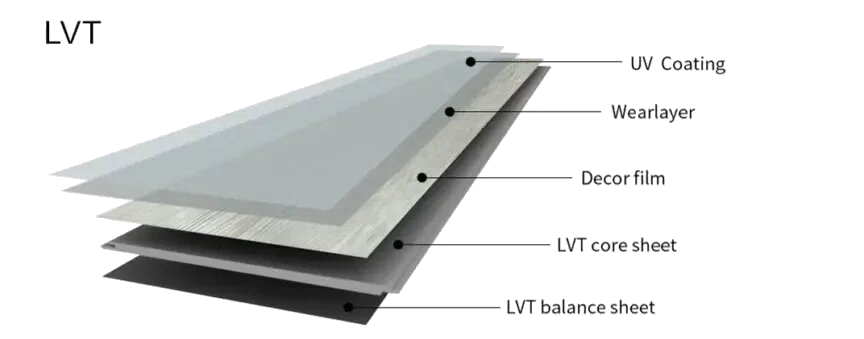

2. Demolition of the structure and three layers: thickness and technology are the core

Wear-resistant layer

Household 0.2-0.3mm (wear resistance is ≥6000 rpm), commercial 0.3-0.5mm (≥10000 rpm).

Preferred UV-coated matte model with double lifts of anti-fouling and anti-slip.

Printing layer

3D high-definition printing, the wood grain annual rings and stone texture transitions naturally, without pixel grain.

Be sure to have solvent-free ink, the formaldehyde content is less than 10mg/kg, and there is no irritating odor.

Substrate layer

The key stroke only leaves shallow marks, and the elastic recovery rate is ≥95%.

Small apartments are lightweight, and large apartments are available in 4-5mm thick, and large apartments are available in thick versions to enhance the feel of the feet.

3. Verify the qualification and check the certification: Reject three-no products

Environmental protection certification: Domestic E1 grade (formaldehyde ≤1.5mg/L), mother and infant families are preferred FSC certification (≤0.5mg/L); internationally recognized Floor Score (VOC strict control), CE certification.

Performance report: EN 660-2 wear resistance test, B1 class flame retardant testing (commercially required).

Anti-counterfeiting traceability: original packaging + anti-counterfeiting code, scan the code to check batch quality inspection information, and refuse bulk final goods.

4. Three practical measures to determine the pros and cons

See

The same style of texture should be random, the splicing gap is less than 0.5mm, and the surface is flat and there is no difference in height.

Touch

The wear-resistant layer is smooth and has a fine grainy feeling (anti-slip design), and the substrate is bent in half without cracking or permanent crease.

Smell

The newly unpacked packaging only has a slight resin smell and will dissipate after 1 hour of ventilation; the pungent and sour smell is that formaldehyde exceeds the standard, so it is decisively ruled out.

5. Install after-sales avoidance: three-point product and seven-point package

Installation method: The self-adhesive model requires floor flatness ≤2mm, and the snap-on type reserves 1-3mm to prevent drumming.

Comparison of installation process between self-adhesive and snap on LVT flooring

| Step | Self adhesive LVT flooring | Buckle type LVT flooring |

| 1Ground preparation | •Clear debris, flatness ≤ 2mm (self leveling beyond tolerance) •Moisture content<3% -5% •The old ceramic tile surface is polished rough | • Same as the left, use putty to fill the old joint and level it •Leave 8-12mm expansion joint on the wall |

| 2Pres-installation planning | • Let the material stand for 24 hours • Planning from the center/prominent wall | • On the same left, draw the center line from the left corner of the wall •Fixed I-shaped/fish bone paving and other methods |

| 3Installation starting point | Paste directly from the planning point, align and press after exposing the backing paper | The first female falcon in the left corner faces inward, leaving a gap of 8-12mm |

| 4Splicing method | Peel and press at the same time, manually align until the gap is ≤ 0.5mm | • Male and female falcon buckle connection•Cut the starting block of the second row in half (avoiding through seams) •Tilt 30 ° and hammer to fix |

| 5Obstacle handling | Cut the shape on site and paste it | After cutting, fasten the buckle and retain the expansion joint |

| 6Expansion joint treatment | • Fill the joints with sealant in damp areas • Skirting board covers the edges | • Must leave 8-12mm seam (wall/column edge) •Skirting board/buckle cover |

| 7Tool requirements | Rubber hammer, art knife, ruler, humidity detector | Rubber hammer, tape measure, cutting knife, hook tool (auxiliary buckle fastening) |

| 8Applicable scenarios | • Small spaces, temporary renovations DIY • Avoid high-frequency water immersion areas | • Large scale, commercial, high stability home decoration • Waterproof version available for kitchen/bathroom |

| 9Efficiency | Single person daily area of 15-20 square meters (simple process) | Single person daily 10-15 square meters (with complex buckle alignment) |

| 10Key points | • Prevent one-time bottom paper from sticking to adhesive • High humidity with moisture-proof film | • The buckle needs to be fully engaged •Adjacent seams staggered by ≥ 30cm |

Accessories: Southern Addition 0.3mm PE moisture-proof film, seams overlap 10cm seal.

After-sales warranty: at least 5 years warranty, keep sample samples for repair and matching patterns.

Conclusion

When purchasing LVT floors, remember: scene priority, structure as the basis, certification as the shield, and actual measurement as the test. Reject the low-price trap and focus on core parameters to choose an ideal floor with both appearance and performance. If you need personalized recommendations, please leave a message to share your decoration needs!